BUTT CONNECTOR

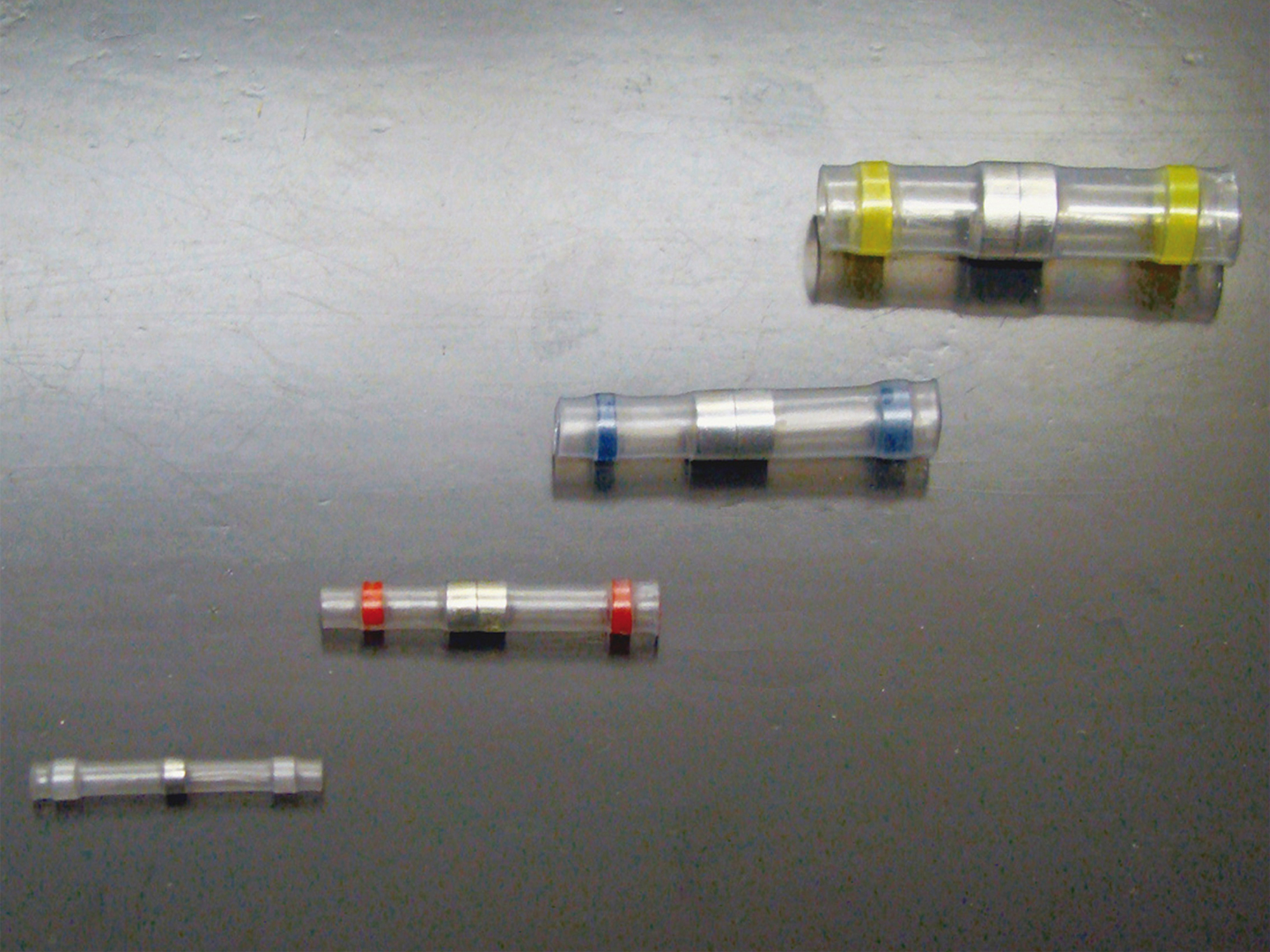

Shrink/Solder Connectors

Unique shrink/solder connector with thermoplastic adhesive rings and internal hot-melt glue. Ideal for producing joints which must stand up to particularly adverse environmental influences. The connectors have an excellent resistance to abrasion, as well as a high strain relief due to the bond with the cable insulation. Butt Connectors prevent voltage loss and can be used for flexible and solid conductors.

BUTT CONNECTOR

Heat-Shrinkable Solder Butt Connectors

Special Features:

- Joining, soldering and sealing in a single operation.

- Extremely easy to install. The quality of the connection can be visually checked.

- Excellent protection against corrosion, UV rays, water, chemicals and acids.

Areas of Application

Plant construction, lifting and conveyor systems, stereo systems, mechanical engineering, motor vehicles, municipal technology, trailer and caravan construction, light and switch cabinet construction, racing. etc.

Application Examples

- Cable splices and shield connections.

- Installation of alarm systems and radios.

- Installation of trailer hitches.

- Installation and repair of electrical equipment.

- Installation of illuminated signs and lighting.

- Watertight installations on outboard motors.

- Mounting accessories on ATVs, quads and motorcycles.

Instructions for use

A hot air blower is recommended for processing. A lighter is sufficient for smaller diameters. Heat around the connection evenly. Strip 10-12 mm of cable. Push the wires into the Butt Connector and press the solder rings flat, so that the connection has a firm hold. Heat the solder rings until they are completely melted. Then shrink the isolation until the O-rings are properly closed. After cooling, check the tightness and the good flow of solder.