HTS PASTE

Polysiloxane Lubricant

Clear, neutral, thermally stable Silicone Paste. Suitable for use as lubricant, grease, protector and sealant. Specially developed for the lubrication and separation of plastics and rubbers with each other or in combination with metals or non-ferrous metals. HTS Paste prevents breakage and freezing, protects against bonding and impregnates a variety of surfaces. HTS Paste is anti-static, dust-resistant, water repellent, does not resinify and protects against humidity and corrosion. HTS Paste is resistant against steam, diluted acids, alkaline solutions and gases.

- Contains no solvents and is free of toxic ingredients.

- NSF certified product according to food regulation H1. Registration No. 162004

This product is acceptable as a lubricant with incidental food contact (H1) for use in and around food processing areas. - Temperature resistance: -50°C to +220°C (intermittent +270°C)

HTS PASTE

Lubrication & Maintenance Paste

Special Features:

- Consists of high purity silicone fat with non-hazardous, temperature stable additives.

- Is chemically inert and has excellent hydrophobic properties.

- Possesses excellent lubrication and sliding properties.

Areas of Application

Electrical engineering, heating and power plants, sanitary instalations, climate and refrigeration, automotive technology, mechanical engineering, metal construction, precision engineering and model construction, marine, industry and craft, building maintenance, production facilities, food industry and waterworks. etc.

Application Examples

- Easing assembly and disassembly of sensitive components.

- Installation of profile rubber and cable lead-throughs.

- Lubricating rolling and sliding bearings with low bearing pressures.

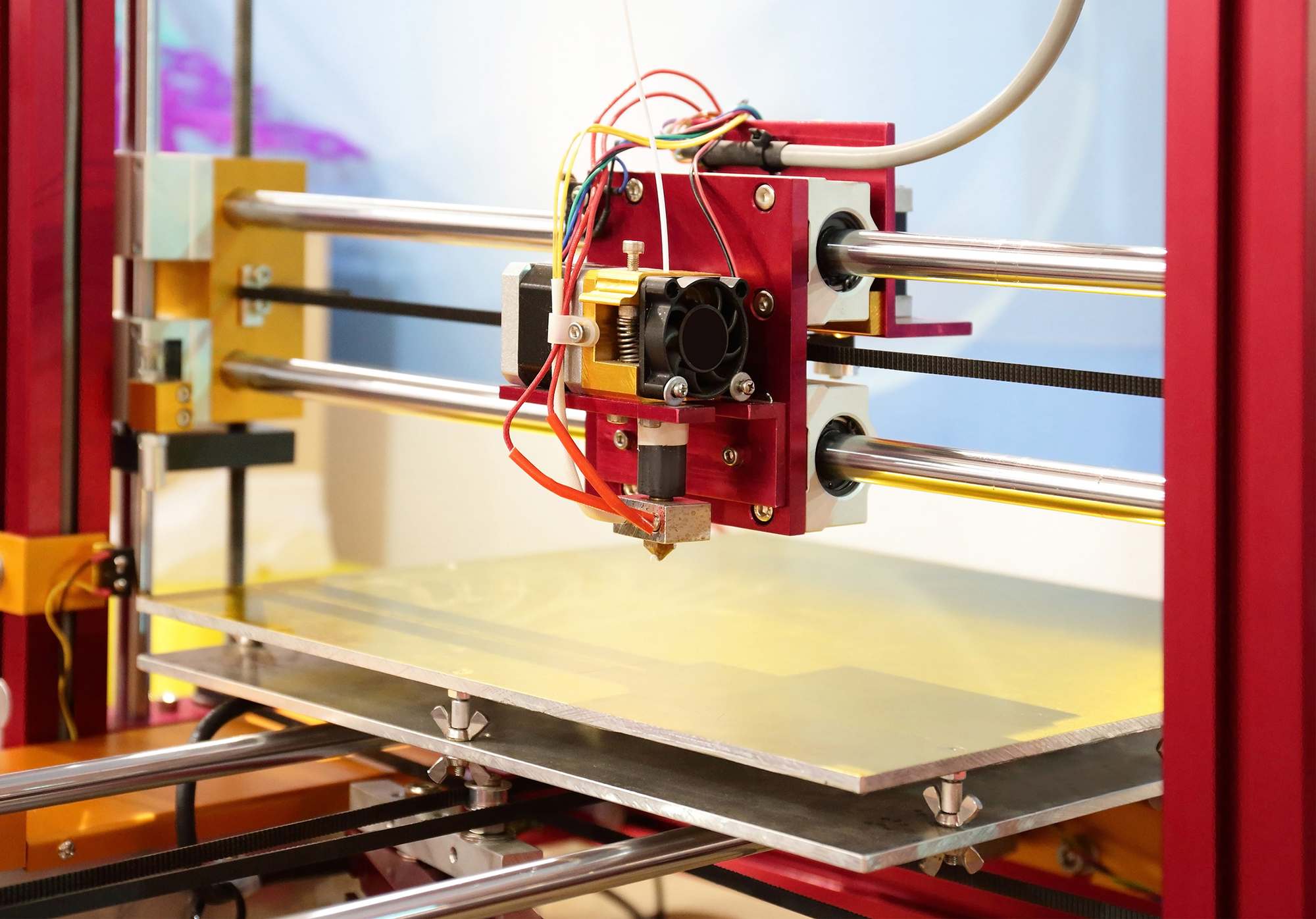

- Lubricant for guides on printer technology and for training appliances.

- Protection against freezing and drying-out of door and window rubbers in vehicles and buildings.

- Lubricant for precision mechanical parts, circuits, valves and equipment.

- Assembly of seals in stainless steel tubes and chimneys.

- Lubrication of fittings, valves, joints and seals in cold and hot water systems.

- Maintenance of plastic, wood, leather, Formica, glass, stainless steel surfaces and carbon parts.

- Maintenance of profile rubber and guide rails in ovens and of stainless steel blades in cutting equipment.

- Maintenance of brewing units and seals in coffee machines and milk containers.

- Maintenance of hoses, O-rings and seals in aquarium and pond pumps.

- Lubrication of O-ring seals in flashlights and underwater cameras.

- Release agents and sealants for valves and seals.

- Lubrication of drawer slides made of wood or metal.

- Lubrication of sunroofs, seat guides, seat belts, door hinges and push rods.

- Protection from weathering of garden and terrace outdoor lighting.

- Protection against weathering on all bare metal contacts on antennas and satellite systems.

Instructions for Use

In order to achieve an optimal result, it is recommended to clean the parts first. Dirt and other lubricant residues must be removed. Then apply the product evenly with a brush, spatula or cloth thinly onto the surface. The pen version is suitable for very fine work, where the product can be applied directly. Note: Treated surfaces can not be painted or bonded.