DTX Tape

Closed-cell, radiation-crosslinked foam strip for the manufacture of high-strength connections between a variety of materials. For all appliactions requiring an immediate adhesive strength. Provides excellent adhesion, high permanent adhesion and excellent resistance against water, diluted acids, bases and mineral oils.

DTX prevents light penetration on joints and splices, is crack-resistant, compressible and permanently elastic.

DTX Tape

Double-Sided Tape

Special Features:

- Suitable for protection against vibration and chafing.

- Protects against dust and dirt.

- Excellent protection against material wear and damage to paintwork.

- Resistant to ageing, heat and plasticisers.

Application Areas

Automotive industry, machine and metalwork industries, air conditinging, store construction, exhibition construction, sanitary trade etc.

Application Examples

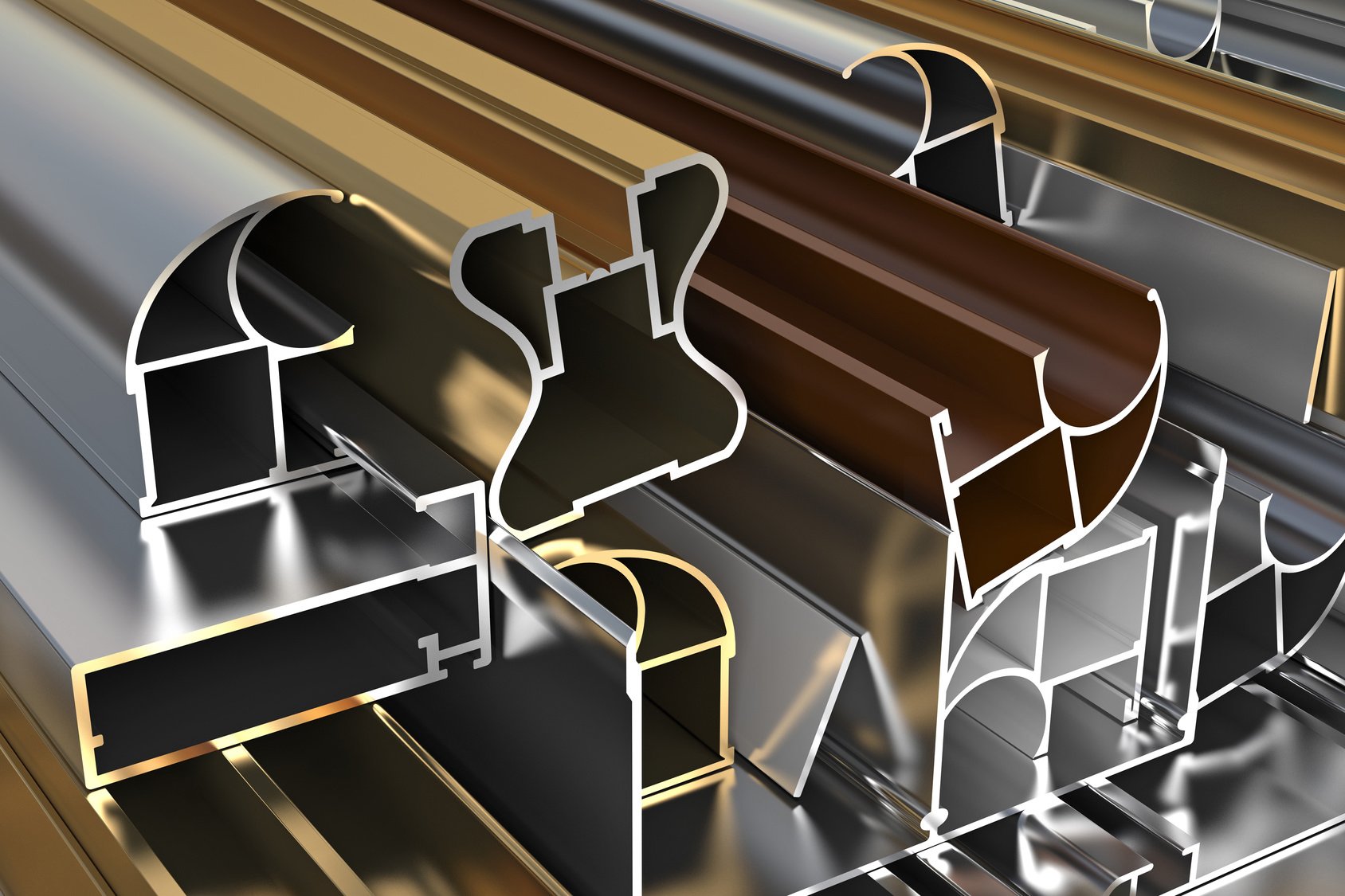

- Applying emblems, profiles, hooks, mounts, fairing, cowling, and decorative elements and strips.

- Sealing control cabinets and housings.

- Permanent assembly of panels made of glass, steel, aluminium and polar plastics.

- Installation of metal or non-metal cover strips.

- Assembly of side panels, number plate strengtheners and truck spoilers.

- Mirror assembly and furniture manufacture.

Instructions for Use

The surface should be clean, dry and free of contaminants such as oil or grease. Release agents such as silicone, paraffin or wax must be removed. Material-friendly solvent should be used as cleaning agents such as benzene or alcohol. The best processing temperature lies between 15 ° C and 30 ° C. The best adhesion is achieved on polar smooth surfaces. Apply only to clean, dry and grease-free surfaces. Condensation must be avoided. (Condensation can occur in the transition from cold to warm rooms). Care must be taken to choose the correct size of tape depending on the nature and weight of the parts to be connected. For mirror adhesion: min. 70 cm2 Tape / 1 kg in weight.