COPPER SEAL ®

Special adhesive for the quick and easy installation of water pipes and for use in confined spaces and fire-prone areas.

COPPER SEAL possesses good resistance against chemicals, solvents, liquid gas, water and hydrocarbons.

Areas of Application:

Heating and plumbing trade, prefabricated buildings, industry and trade, arts and crafts, production facilites, maintenance and building services, food technology, water works, etc.

Application Examples:

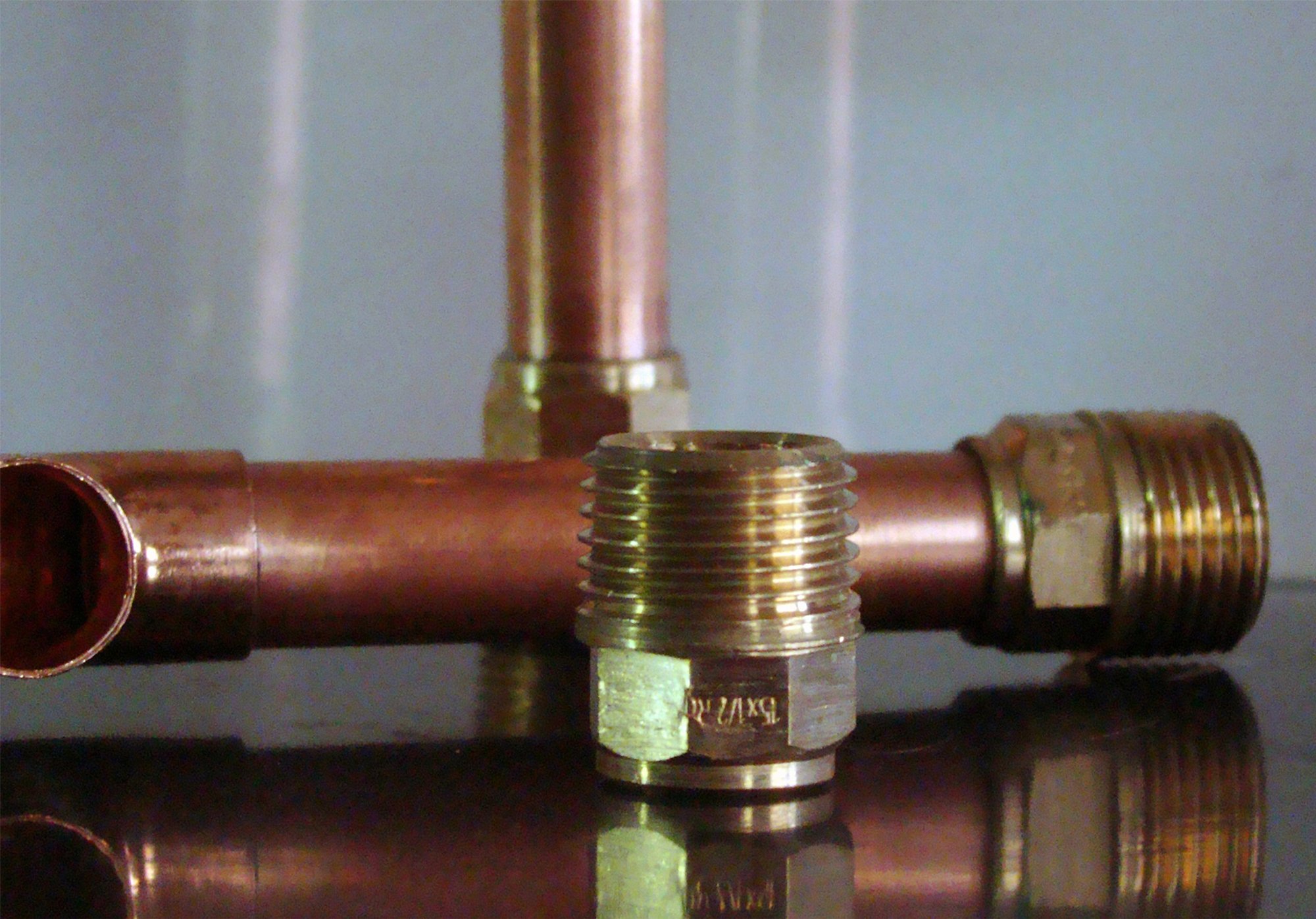

- Bonding push fittings and pipes made of copper.

- Installation and repair of water lines in wooden and prefabricated buildings.

- Securing metal threaded connections in water heating systems up to 85°C.

Copper Seal

Anaerobic bonder designed for solder-free bonding of copper pipes and fittings on cold and hot water lines

Besonderheiten:

- Prevents oxidation.

- Is economical in use and shortens the installation and repair time by around 75%.

- Recommended for copper fittings with or without threads.

Instructions

The surface should be clean, dry and free of contaminants such as oil or grease. Shake product well before use.

Assembly

Pipes and Fittings:

Roughen the parts to be bonded with grain 100/80 sanding paper, so that there is enough surface for the adhesive. A solvent-based cleaning product (acetone etc.) is recommended to remove existing dirt and dust. The product should be applied to the pipe fully and as a small adhesive ring to the fitting. The adhesive ring serves equally as a lubricant.

Pipe Threads:

Apply the product to the thread in a 360° ring, while leaving the first thread free. Ensure that the spacing between the threads is sufficiently filled. For coarse threads it is also recommended to apply the product to the internal thread. Tighten the connection as usual and remove any product residue. Properly tightened connections have an immediate sealing effect against low pressures.

Disassembly

Heat the joint locally to approx. 250°C and disassemble while warm.

Storage

Anaerobic products must be stored unopened in a cool and dry room at a temperature between 8°C to 28°C. The shelf-life of these products is at least 1 to 2 years (in accordance with the above mentioned storage conditions). Product residues should never be filled back into the original container in order to maintain the original product properties.

Additional Information:

- Finally assembled connections should not be realigned. Should it be necessary to remove the fitting, the joint should be removed and cleaned completely. The joint can then be re-assembled with a new product application. This product, along with other liquid or anaerobic sealants on the market, is not allowed in Germany for gas housing installations as per DVGW-TRGI 2008, as a realignment of pre-assembled threaded joints is not possible. Identification: Not allowed in Germany for gas housing installations.

- These products are not suitable for pure oxygen and/or oxygen systems and should not be used as a sealant for chlorine or strong oxidizing media. Cracks can occur when used on thermoplastic materials. It is recommended to check the compatibility with such materials.